The 2019 models are in. Dynamic. Stylish. Performance-inspired.

Are we talking about cars? Nope. We’re describing the latest in commercial inkjet printing equipment. Print production is having its moment and today’s color inkjet is its Ludicrous Mode.

Print production innovation matters, a lot, because print remains a dominant channel for outbound customer communications. Some of this is due to legal and regulatory requirements: Compliance requires you to send certain documents through the mail.

But even for our clients that offer digital delivery options, which are necessary to build interactive customer experiences, print is still a vital component of an omnichannel strategy. Forrester’s Craig LeClair says for companies using CCM, 80% of their customers still receive paper communications.

Faster and better

Digital inkjet is the industry’s fastest-growing print process and investments in this technology, at $1 to $2 million per printer (depending on finishing equipment to sheet and perf), delivers immediate customer impact. Production inkjet boasts high-quality, high-volume variable content printing at tremendous speed. Up to 1,000 pages per minute – with better color accuracy and consistency, along with cost-effective digital color.

As inkjet improves, it’s tackling more applications in graphic and commercial print and is responsible for huge growth in the color production market, according to IDC’s Amy Machado. A new inkjet printer can replace two or three toner devices.

Disruptive technology

Older production technology, whether cut sheet or roll fed, often requires printers to produce work using pre-printed color shells fed into the printer. Then content and variable data are added using black-and-white toner machines.

In addition to making color production costly, this technology limits flexibility. Once a company has made an investment in, say, 100,000 of these preprinted shells, it’s likely to continue using them even if branding or messaging has evolved; instead, it’s common to try to deplete inventory levels to avoid having to dispose of unused forms and wasting money.

An inkjet press, on the other hand, can be configured as a roll-to-cutsheet machine with dynamic in-line perfing and dual engines for duplex printing. With inline/one-pass personalization, the printing is completed in one run: less labor moving pieces on and off the press, no shells, no registration errors, no extra drying time.

As a result, inkjet offers full variable color-on-demand so users can print on white paper and change a document’s messaging on the fly. [Read our related post Color is the New Black in Communications.] And it makes it easier to leverage data sets to include targeted messaging in transactional mailings, eliminating the costs of an additional color mailing and possibly impacting the effectiveness of the piece itself.

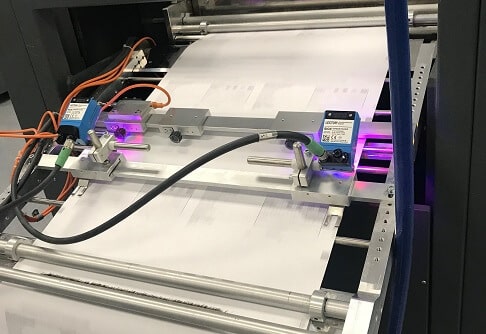

The technology poses unique challenges. It demands that almost every facet of a printer’s organization change–workflow and job processing, QA procedures, material movement and the complete production processes. For example, the printer itself runs so fast, if using a continuous roll-fed inkjet format, you can’t stop and pull a page for quality control as in a cut-sheet process.

There’s an app for that, however. A high-speed camera connected to the printer manages page capture and archiving to allow spot checks without interrupting production.

Making production investments

Nordis continues to invest in technology solutions for every step of the communications and payments process, including print production technology. After attending various printer manufacturer and industry trade shows this fall, we’re preparing to bring online one of the newest inkjet models in 2019.

With print still king of the road, production inkjet is its muscle car. More than half of all digital production color volume will be printed on inkjet devices by 2019, according to digital print consultancy I.T. Strategies.

See you in the fast lane.

About the Author

Mike oversees production operations, warehouse facility and data processing. He is a 25-year direct-mail industry veteran whose focus on streamlining production has helped the company and its clients reduce cost while increasing efficiency and output.

Prior to joining the company in 2009, Mike already had an impressive track record managing production operations, data processing, and client services departments for Access Direct Systems, Inc.; Antares-ITI; and Design Distributors, Inc.

Mike earned a bachelor of science in marketing, with a minor in management, from Colorado State University. He is a member of the Mailing Fulfillment Service Association and the Postal Customer Council.